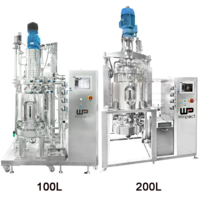

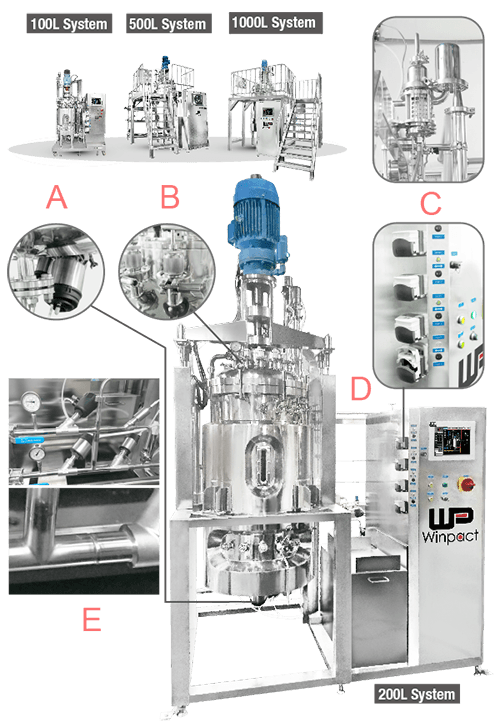

100L/200L Pilot Scale SIP Fermentation System

Product

- A. Harvest valve sanitary level diaphragm valve

- B. Detachable aseptic feeding device

- C. Mechanical seal lubricate and automatic cooling device

- D. Pump

- E.

- - Pneumatic valves for accurate and automatic control

- - Orbital welding provides top quality

|

|

|

|

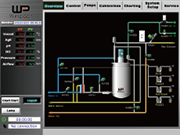

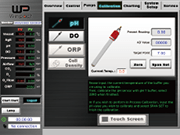

| Monitor page for operation overview | Automatic and manual operation | Automatic sterilization process | Online system calibration |

Winpact offers pilot and production scale bioreactor/fermentation systems for all of your large scale fermentation needs. Our standard SIP Production Scale Fermentation System is constructed with BPE standard piping with orbital welding and top grade automatic valves to allow stable and repeatable result for every experiment. All of our features are designed to provide a high level of productivity and automation while maintaining a low operation cost. All other great features including total sterilization process, mechanical seal break indication, golden vessel ratio design and complete selection of optional devices for optimizing the fermentation process.

Major Science SIP Fermentation Systems

- Wide range of vessel selection, from 100 L and 100L working volume

- Multi-lingual 12” and above colored graphical control interface

- Fully automated process with remote monitoring

- 15-step automatic program setting

- Orbital welding ensures minimal residue buildup

- Highest grade construction with Stainless Steel SUS316L

- Hive jacket design provides astounding temperature control

- Exhaust pressure relief valve for maximum safety precaution

- Multiple safety design integration for peace of mind operation

- Remote monitoring & controlling software free from purchase

- Password protection for multiple users with customized access levels

- Various optional devices for process optimization and needs

- Ethernet communication with Winpact SCADA software, and IP address

| Capacity | 100L | 200L |

|---|---|---|

| Total volume | 120L | 268L |

| Working volume | 100L | 200L |

| Vessel and jacket maximum working pressure | 3 bar (43.5 psig) / 3 bar (43.5 psig) | |

| Type | Double layered fully enclosed capsule-type tank, with an outer temperature protective layer | |

| Material | Direct contact to medium - 316L stainless steel; all others - 304 stainless steel | |

| Surface finish | Interior polish ≦ 25 Ra/in (0.6 μm) Mechanical polishing; Electropolish optional Exterior polish ≦ 32 Ra/in (0.8 μm) Mechanical polishing; Electropolish optional |

|

| Ports | Ports designed according to user requirements | |

| Piping and valve materials | Parts that directly contact with the product/medium uses 316L stainless steel (≤25 Ra/in) internal polished tubing (BPE standard) :

A. Constructed with 304 stainless steel |

|

| Controller | 12” color industrial touch screen | |

| * User-friendly, graphical control interface * Includes secure user accounts, with different levels of access * Use stainless-steel controller cabinet (100 L and above only) * Modularized and standardized design (Module Skid): ergonomically designed according to height, ease of vessel clean up, and ease of extraction in relation to vessel bottom valve * Includes maintenance page with system diagnostics * All programmed setting values are automatically stored into the built-in memory; the settings will not be lost in case of power outage/interruption. When power is restored, the interrupted process will automatically resumed |

||

| Setting | * Automated sterilization process * Automated fermentation program |

|

| DO | * Control range: 0-100%, adjustable * Software electrode calibration, with automatic temperature compensation function * Includes one set of side-inserted stainless steel autoclavable DO electrode * DO Stat features with intelligent feeding |

|

| PH | * PID control with adjustable deadband * Control range 2.00 to 12.00 pH, ±0.01 * Calibration function with automatic temperature compensation function * Includes one set of side-inserted, autoclavable pH probe with stainless steel housing * pH Stat features with intelligent feeding |

|

| Pump | * Built-in peristaltic pumps * Each feeding pump can run adjustable 15-step program * Each pump can be adjusted for speed, forward and backward direction, and manual or automatic mode * Each of the four peristaltic pumps can be designated for different functions: acid pump, base pump, antifoam pump, or substrate feeding pump * Optional fifth and six peristaltic pump available |

|

| Temperature | * Vessel temperature is measured with a side-inserted PT-100 temperature probe and maintained using PID control. Measure range: 0-130℃, ±0.1℃, Operational range: 0-60℃, ±0.1℃. |

|

| Agitation | * Manual or automatic control of agitation speed * 15-step program to change speed, or use DO cascade control |

|

| Air supply and exhaust | Gas supply and dehumidifer: uses in-house air compressor or air dehumidifier * Includes re-useable, autoclavable 0.2μm air filter for gas inlet * Gas Inlet (air) Includes mass flow controller: 2 vvm maximum according to the vessel capacity * Gas Inlet (oxygen) Includes pure oxygen rotameter (manual flow control): 1 vvm maximum according to the vessel capacity * Includes oxygen gas solenoid valve, with automatic pulsed time control Air outlet / Exhaust * Exhaust port with stainless steel condenser * Includes re-useable, autoclavable 0.2μm air filter * Includes automated adjustable gas outlet valve to adjust vessel back pressure * Can control manually or automatically via software |

|

Utility Requirement

| Capacity | 100L | 200L |

|---|---|---|

| Power | Three phase 220V or 380V (note: can be customized to local standard) | |

| Air | At least 7 bar | |

| 300 L/min flow rate |

600 L/min flow rate |

|

| Dehumidified | ||

| Oil-free | ||

| Peripheral factory water supply | Cooling water (tap water, at least 15oC below working temperature, must be soft water); Pressure at least 2 bar |

|

| Process water | RO Water | |

| Plant steam | ≥ 2 bar; dry steam with no entrained condensate | |

| Process steam | ≥ 2 bar; dry steam with no entrained condensate | |

| Drain | In situ drain; ≥ 2" | |

* Customization on the SIP Fermentation system available upon request.

* Please contact your regional manager for evaluation request.

* For bigger capability systems. please contact Major Science and/or our distributor partners.

Optional Accessories Items

Gas Mixing Station

The gas mixing station allows the user to optimize cell growth conditions by independently supplying up to four gasses to the fermentation process. Parameters such as dissolved oxygen and pH can be controlled by adjusting the gas composition supplied to the system. Four manually adjusted flowmeters control the flow rate of each gas, while the 4 solenoid valves automatically open or close in response to the culture conditions. The Gas Mixing Station can be operated in either manual or automatic modes.

Oxygen Mass Flow Controller

Maintain optimal control over culture DO level by installing this optional mass flow controller. The mass flow controller can accurately adjust the flow rate of incoming oxygen and is resistant to fluctuations in gas pressure, ensuring precise control and repeatibility of experimental conditions

- A. Cascade control scheme

- B. Integrated into controller for simple and automated operation

CO2 / O2 Off-Gas Analyzer

The CO2 / O2 off-gas analyzer provides real-time measurement of carbon dioxide and oxygen concentration of the bioreactor exhaust gas. The CO2 concentration is determined using a self-calibrating non-dispersion infrared sensor, while an electrochemical sensor monitors the oxygen concentration. Using this information, the user can continuously monitor metabolism and analyze cell growth parameters.

Cell Density Monitor

Our special implemented online cell density device allows you to obtain direct information about your cell growth rate and cell density; as these values are critical to many bacterial, yeast and animal cell cultures. Online cell density device combines monitoring and probing system, also performs accuracy precisely. Having trouble determining the cell growth rate? Our online cell density is the key to your solution.

ORP Probe

The ORP probe measures the oxidation-reduction potential of the fermentation media, which is a crucial indicator of anaerobic conditions/reactions. This low-maintenance and sterilizable probe is designed to withstand repeated experiments.

Electropolish (EP) of Vessel Tank

Electropolish of the vessel tank is offered as a higher sanitary grade surface finish. EP surface finish is an addition to the standard mechanical polish (MP) which provides a smoother surface area to minimize residual residue.

* Note that this option MUST be requested at your initial inquiry, later-on additions after completion of construction is not possible

Transfer Piping

Transfer piping of your resulting product/medium between vessels is offered for the convenience of operation.

Automated transfer using pressure in addition to directional control with valve regulations offers fast and easy operation.

Turbidity Probe

The turbidity probe measures the turbidity level of the fermentation media, which provides you an indication for the metabolic reaction and in terms allows you to maintain a steady cell level.

Load Cell

The load cell provides weighing capability to your fermentation process. Weighing the substrate feeding can indicate how much substrate was added during the fermentation process, which allows the user to provide more accurate control accordingly to what the process needs.

Operation Platform

An operation platform is offered to provide optimal operation convenience. Stainless steel constructed platform offers elevated height for full observation of the headplate when standing on the platform, the chest-leveled positioning of the vessel headplate prevents falling into the vessel.